Custom Metal Fabrication

Our fabricators are trained on an array of machines, and are prepared to manufacture any design you can imagine.

Give us your blueprint, or have us develop one for you – and we’ll bring your product to life!

METAL SCISSOR BAND SAW

• Works with aluminum, steel, and plastics

• Ideal for processing raw materials

• Produces clean, smooth edges on cuts

PRESS BRAKE

• Works with sheet metal

• Ideal for thin substrates

• Bends metal to create duct work, tubing,

and other cylindrical formations

ROLL BENDER

• Works with sheet metal and barstock

• Creates rings from 6.5 inches to 70 inches

PROFESSIONAL WELDING

You need a product that meets your specifications and can be manufactured to support the demands of your supply chain. From complex welds to basic assembly, our extensive experience means we can meet any deadline without compromising performance.

MIG WELDING

• Works with steel, stainless steel and aluminum

• Versatile processes

TIG SPOT WELDING

• Ideal for thin substrates

• Highly versatile and can work with any thickness or position

ROBOTIC WELDING MACHINES

• Works with aluminum and steel

• Unmatched speed and consistency

• Guided by our experts for

superior performance

CNC HI-DEF PLASMA CUTTING MACHINE

• Works with steel and stainless steel

• Ideal for thick substrates

• Delivers exceptional precision

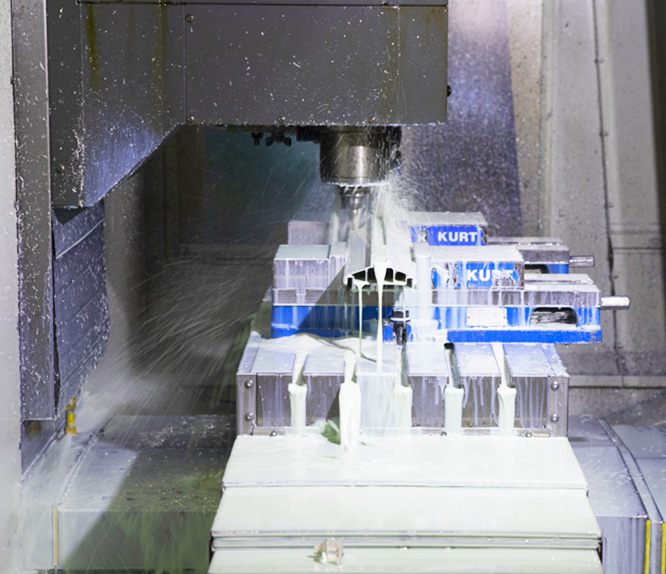

CNC & Manual Machining

We utilize state-of-the-art CNC lathes and CNC vertical machines for both intricate and simple metalwork. Our technicians are trained in operating both CNC and manual milling and drilling machines to meet your exact specifications.

CNC HORIZONTAL LATHE

With Automatic 6' Bar Feeder

• Works with aluminum, steel,

stainless steel, and plastics

• Limitless capabilities

• Automation delivers fast,

consistent results

PUNCH PRESS

• Works with aluminum, copper and steel

• Created precise 3-D shapes in metal

• Ideal for coil stock

TURRENT PUNCH

• Works with aluminum, galvanized steel,

and stainless steel

• Ideal for thin substrates

• Precisely cuts shapes and designs

Cleaning & finishing

When cleaning, we find sand blasting and glass bead blasting can remove even the most stubborn debris.

After cleaning, we finish products with vibratory deburring, to keep surfaces smooth. We then arrange plating and coating for a finished, clean product.

Design & Quality Assurance

We’ve built our name on quality – so when it comes to QA, we never cut corners! We have some of the most advanced machinery available, allowing us to achieve the tight tolerances often required in industrial fabrication. And our rigorous processes and procedures ensure that you’ll only receive the highest quality products.

As a part of our quality assurance process, we will create a drawing in a CAD software, such as Solid Works or SolidCAM. This ensures a quality product, built to spec, every time.

Tube Forming/Bending

We have the capabilities to form and bend tubes for a variety of applications from large to small.

Whether your application is in health and fitness, agriculture, or construction, we can create a product that fits your needs.